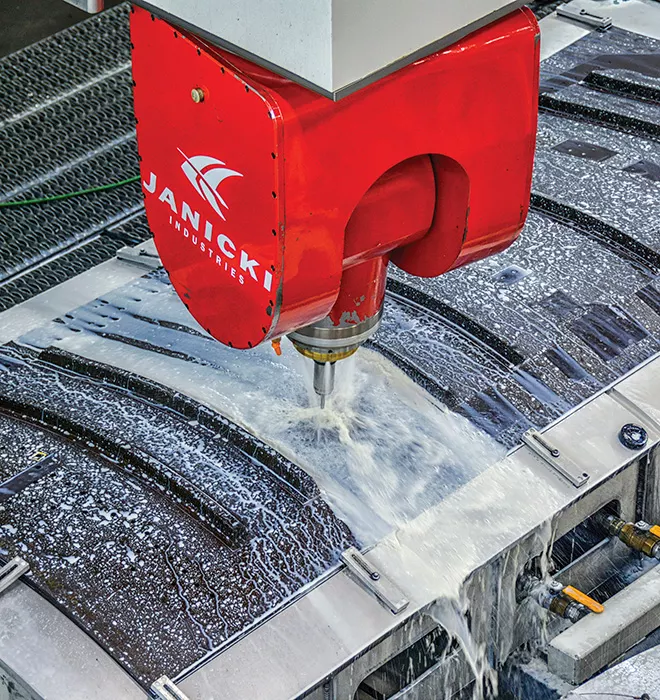

5-Axis Milling

Unprecedented Accuracy on Large-Scale Projects

Janicki’s 5-axis machines’ superior scale and precision capabilities are a result of our custom design and development of all the machines’ major components: mechanical, software and electronics/servo-control mechanisms.

Our machine capacities are among the largest in the world, with a maximum envelope size of 100’ x 20’ x 8’

Our proprietary, internally developed, CNC software uses custom volumetric error compensation algorithms that provide unprecedented accuracy on large-scale projects.

Machine positions are controlled by servo mechanisms with extremely high-resolution optical encoders. The resolution of these encoders is better than 0.000012 inches (0.312microns). As a matter of reference, a single sheet of paper measures .003 inches.

Unlike most other 5-axis mills, our wrists incorporate what we call contra-torque – each wrist joint has two motors that oppose each other. This contra-torque arrangement eliminates all back-lash within the wrist, removing vibration and acceleration problems.

We use Leica laser trackers to measure the volumetric Cartesian errors. Whether cutting composites or trimming exotic metals, these devices have accuracies of approximately 0.002 inches (51 microns) in our working envelope.

Janicki employs a team of automation and controls engineers who fine-tune the dynamic performance of our machines to achieve high accuracy while the machine is in motion and under load.

| JANICKI MILLS | ENVELOPE SIZE |

|---|---|

| Mill #1 – WA | 68ft x 19ft x 8ft |

| Mill #2 – WA | 88ft x 19ft x 8ft |

| Mill #3 – WA | 40ft x 12ft x 5ft |

| Mill #4 – WA | 57ft x 14ft x 7ft |

| Mill #5 – WA | 100ft x 20ft x 8ft |

| Mill #6 – WA | 100ft x 20ft x 8ft |

| Mill #7 – UT | 18ft x 14ft x 6ft |

| Mill #8 – UT | 18ft x 14ft x 6ft |

| Mill #9 – UT | 80ft x 14ft x 6ft |

| Mill #10 – UT | 60ft x 8ft x 4ft 8in |