2025 Engineering Internship Overview

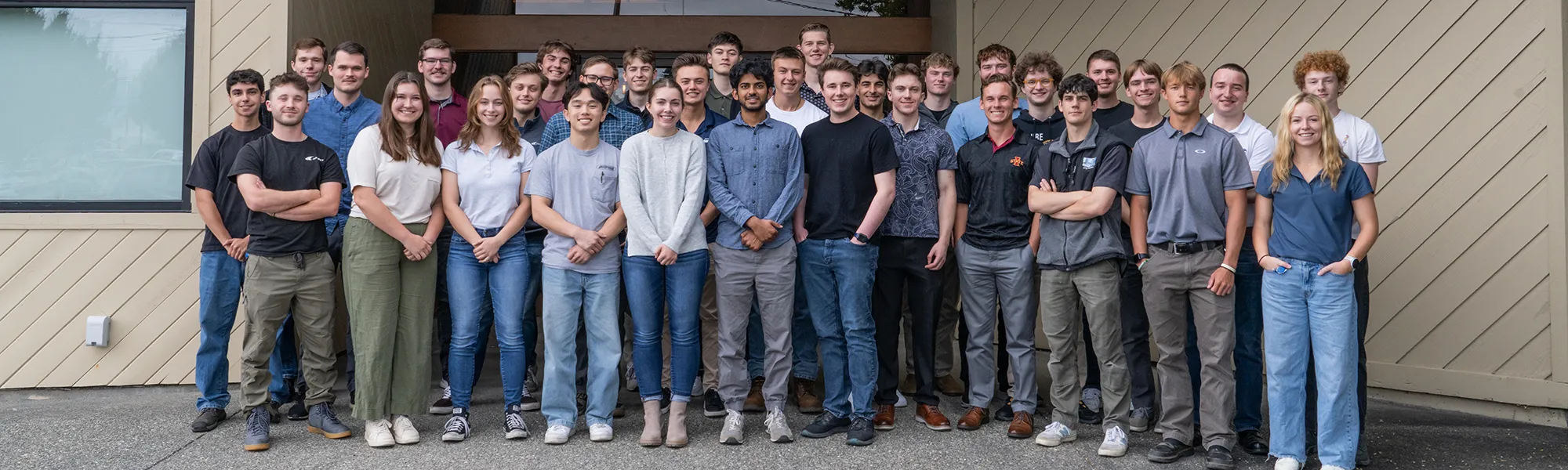

This summer, Janicki welcomed more than 40 engineering interns from universities across the country for a 10- to 12-week program. Engineering interns, typically further along in their degrees and with some hands-on experience, were integrated directly into our engineering teams. They took on individual projects, collaborated with seasoned engineers, and presented their work to colleagues before the end of the summer. Each experience was tailored to the intern’s interests and skill set, giving them the freedom to explore and contribute in meaningful ways.

With summer coming to a close, it is time to reflect on the many events Washington-based interns also had the opportunity to experience. The goal of these activities was to provide interns with career insights, meaningful connections, and a deeper look at the Janicki community.

Coffee and Donuts Kickoff

Coffee and Donuts Kickoff

In June, Janicki launched the engineering internship program with a Coffee and Donut event. This was the first time the full engineering intern cohort came together, with Washington interns attending in person and Utah interns joining online. The event included a panel of three Janicki engineers, Isabel, Zach and Hayden, who all started as summer interns. Interns had a chance to connect with professionals who once shared their experience while enjoying some breakfast treats.

Each panelist shared their personal and professional journeys before opening the floor to questions. Many questions focused on work-life balance, tips for working with different leadership styles, and transitioning from student to workforce. Hayden, known as Janicki’s “OG intern,” has been with the company full-time for more than five years. His standout advice, “Use your time off well! Get out there and explore your hobbies,” set the tone for the summer. Interns were reminded that their time at Janicki is more than a summer job; it is a launching pad.

Executive Meet and Greet

In mid-July, Janicki hosted its second summer intern event: the Executive Meet and Greet. Three members of the executive team, Kevin, Robbie, and Mike, sat down with the engineering interns to share their journeys, swap experiences, and answer questions. Each vice president shared their personal background, why they pursued engineering, how they navigated career opportunities, and how they ultimately arrived at Janicki in their current roles.

Intern questions ranged from navigating large corporate environments versus smaller companies to career mistakes and transitioning from engineering to management. Mike spoke about “inflection points” in his career, key moments when seizing an opportunity, gaining a new skill, or meeting the right person significantly changed his trajectory. Robbie emphasized the importance of early effort and making the most of free time to maintain work-life balance. Kevin reflected on his lifelong passion for aviation, advising interns, “Find something that gets you to jump out of bed in the morning.”

Intern questions ranged from navigating large corporate environments versus smaller companies to career mistakes and transitioning from engineering to management. Mike spoke about “inflection points” in his career, key moments when seizing an opportunity, gaining a new skill, or meeting the right person significantly changed his trajectory. Robbie emphasized the importance of early effort and making the most of free time to maintain work-life balance. Kevin reflected on his lifelong passion for aviation, advising interns, “Find something that gets you to jump out of bed in the morning.”

The Executive Meet and Greet gave interns rare access to decades of industry experience and practical career advice. Through honest reflections and insights, Janicki’s executives inspired interns to think boldly about their own career paths.

Intern Picnic and Project Presentations

At the end of July, Janicki held the final intern event of the summer, the Intern Picnic. This event allowed interns to mingle, enjoy a meal, and share their summer experiences, projects, and insights. Four interns were selected to present their work.

- Hunter highlighted process improvements, program support, and other contributions.

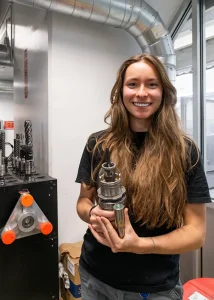

- Rachel shared her work on streamlining the tool assembly process and creating a tool assembly template request form. She also described a personal project with the research and development team, integrating new materials to create a carbon-fiber kiddie pool that fits in the back of a station wagon.

- Gabe and Luke concluded with a joint presentation on nondestructive testing. Luke gave an overview of the method and its application at Janicki, while Gabe detailed a fixture they designed to simplify part inspection.

To close the afternoon, Neil, one of Janicki’s vice presidents, spoke about his journey, from running his own snowboard manufacturing business in college to various experiences before joining Janicki. He emphasized that he values young engineers who go above and beyond and possess hands-on mechanical skills developed through practical experience.

Utah interns also shared their projects and experiences with company leaders during a final presentation. Janie highlighted the range of aerospace-related projects she contributed to as part of the metallics team.

Building Connections Beyond the Workplace

Beyond projects and presentations, the 2025 intern class built strong social connections throughout the summer. Hikes, camping trips, and pizza nights showcased the camaraderie formed in a short time. These events highlighted the interns’ contributions and helped bridge the gap with the corporate environment, fostering meaningful connections.

As they return to their campuses this fall, engineering interns leave Janicki with new skills, a deeper understanding of the industry, and lasting friendships, ready to take the next step in their careers.

Written by Avery, 2025 Human Resources Intern

Are you interested in becoming a Janicki intern? Visit our Internships page for more information.

His interest in the field began at a young age. With a father who is both a civil engineer and a Navy veteran, Ethan was introduced to engineering early on and always felt it was a path he wanted to consider.

His interest in the field began at a young age. With a father who is both a civil engineer and a Navy veteran, Ethan was introduced to engineering early on and always felt it was a path he wanted to consider. At Gonzaga, Ethan is an active member of the

At Gonzaga, Ethan is an active member of the

Her advice for future interns:

Her advice for future interns:

Cory first learned about Janicki at a career fair and was drawn to the company due to his background in composites. He saw the internship as an opportunity to deepen his technical knowledge and gain real-world experience.

Cory first learned about Janicki at a career fair and was drawn to the company due to his background in composites. He saw the internship as an opportunity to deepen his technical knowledge and gain real-world experience.

His day-to-day duties vary at Janicki. Typically, he works with CAD modeling, speaks with technicians, reviews design, processes 3D printing projects and helps on the production floor. He’s involved in several projects this summer, but the main one involves creating a new modified drill jig to improve efficiency on some of the drilling operations.

His day-to-day duties vary at Janicki. Typically, he works with CAD modeling, speaks with technicians, reviews design, processes 3D printing projects and helps on the production floor. He’s involved in several projects this summer, but the main one involves creating a new modified drill jig to improve efficiency on some of the drilling operations.

In his role, Luke works closely with NDI technicians and engineers to define and implement tests that detect material conditions and flaws that could otherwise lead to catastrophic failure in parts. These evaluations are performed in a way that preserves the future usefulness of the object or material. In short, NDI enables inspection and measurement without causing damage.

In his role, Luke works closely with NDI technicians and engineers to define and implement tests that detect material conditions and flaws that could otherwise lead to catastrophic failure in parts. These evaluations are performed in a way that preserves the future usefulness of the object or material. In short, NDI enables inspection and measurement without causing damage. One of Luke’s projects this summer involved designing a fixture to help rotate a part, which helped reduce both labor and time during a specific process. He said he was impressed, and at times, almost overwhelmed by the level of detail involved in every part.

One of Luke’s projects this summer involved designing a fixture to help rotate a part, which helped reduce both labor and time during a specific process. He said he was impressed, and at times, almost overwhelmed by the level of detail involved in every part.

Since then, she has worked on multiple projects for the space team. One of her key assignments involves designing and testing a fixture for a rocket, with a focus on pressure resistance and resolving structural issues such as bridges and wrinkles in the part.

Since then, she has worked on multiple projects for the space team. One of her key assignments involves designing and testing a fixture for a rocket, with a focus on pressure resistance and resolving structural issues such as bridges and wrinkles in the part. She also emphasized the importance of understanding non-engineering aspects of a project, including planning and budgeting. Her advice for future interns: Ask questions frequently and come in with a basic understanding of composite materials.

She also emphasized the importance of understanding non-engineering aspects of a project, including planning and budgeting. Her advice for future interns: Ask questions frequently and come in with a basic understanding of composite materials.

On campus, Rachel is a member of the Baja SAE team, where she works in the machine shop making parts for an off-road vehicle the team builds from the ground up. That hands-on experience has translated well into her internship this summer.

On campus, Rachel is a member of the Baja SAE team, where she works in the machine shop making parts for an off-road vehicle the team builds from the ground up. That hands-on experience has translated well into her internship this summer.

At Janicki, Hunter’s favorite part is the people and the company’s broad capabilities. He appreciates that Janicki has a hand in so many different markets, making it a dream place to intern for undergraduate students who are figuring out what they like and want to go into in the future. He spoke highly of his team’s support, noting how helpful and open they are when he has questions and when correcting his mistakes.

At Janicki, Hunter’s favorite part is the people and the company’s broad capabilities. He appreciates that Janicki has a hand in so many different markets, making it a dream place to intern for undergraduate students who are figuring out what they like and want to go into in the future. He spoke highly of his team’s support, noting how helpful and open they are when he has questions and when correcting his mistakes. One thing that surprised him about engineering was the practical role of an engineer. The jump from the classroom to on-the-job engineering was different than he was expecting. Hunter said that it’s more about keeping processes going, making little tweaks, and solving problems rather than theoretical classroom material. He talked about how he’s developing what he calls his engineering “knack.”

One thing that surprised him about engineering was the practical role of an engineer. The jump from the classroom to on-the-job engineering was different than he was expecting. Hunter said that it’s more about keeping processes going, making little tweaks, and solving problems rather than theoretical classroom material. He talked about how he’s developing what he calls his engineering “knack.”